Testing AV&V™ VSK7000TG Beehive Spring Kit

Testing AV&V™ VSK7000TG Beehive Spring Kit

The V-Rod™ engine is a very well designed unit but with the new cam profiles out there, us at AV&V™ wanted to develop a Beehive valve spring kit that can accept a higher valve lift and withstand higher loads than the stock assembly. There are some aftermarket spring kits available on the market. These spring kits allows higher valve lift but they still use stock style keepers that hold the valve by the grooves resulting in a poor fit betwen the valve and the retainer. One way of improving that system is to change the valves for single groove units and to use a single groove valve spring kit. But that option is pretty expensive.

At AV&V™, after a lot of R&D, we developed a beefer 7 deg. valve lock that actually clamp the valve above and below the 3 grooves. These new valve locks are carefully machined on our CNC lathes and the receive additionnals threatment to enhance their caracteristics.

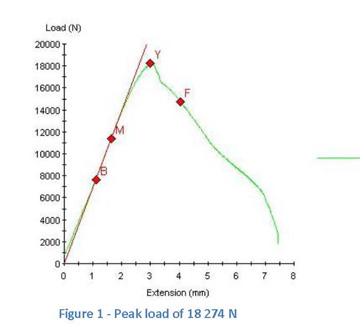

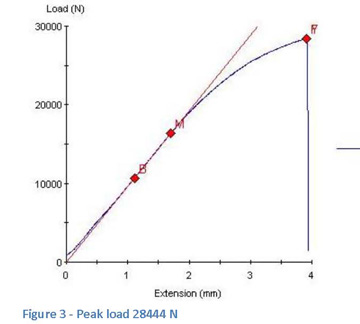

During testing, all tests were executed on a widespread range of retainers and locks were completed with a material tensile strength testing machine (Alliance RF200). All tests were executed at 1mm/min of material elongation. Considering that the data acquisition was operating at 10 Hz, this gives us sufficient data to analyse the assemblies in the post destruction session.

After extensive testing we were glad to see that the results exceeded our expectations.

Take a look at how the AV&V™ valve locks actually “clamp” the valve stem compared to the stock triple groove locksAfter extensive testing we were glad to see that the results exceeded our expectations.

Test result using stock style triple groove locks and stock retainer. Breaking point load is at 18,274 Newton

Test result using AV&V™ new VSK7000TG locks and retainer. Breaking point load is at 28,444 Newton. Sinking and breaking point are 55% Higher than with the stock style components